Adventures in Strawbale Building

The following is a chronicle of our adventures in building a round wood timber frame circular strawbale home on our budding homestead and educational center.

Long Creek Homestead is located on 25 acres of Appalachian heaven in the Blue Ridge Mountains of Maryland, just 5 miles north of historic Frederick. The land is mostly regenerated forest composed of poplar, cherry and black locust which we have built our home from. 75% of the wood for the home was storm fallen from Hurricane Sandy, which hit us in October of 2012, kicking off the design process and building that is still in motion 4+ years later.

*Our home is fully permitted and coded to law

Rubble Trench Foundation

The foot print and foundation for our home is quite simply packed gravel. There is no rebar or concrete in the ground to eventually fail. The oldest buildings on the planet are on stone foundations.

Working the Wood

All the wood in our home was first hand peeled! Mostly by Ashley while pregnant.

Round Wood Joinery

Ninja Wood Working. It took us 7 months to frame the home! It would have been half that if the timbers were squared. Gratitude to master wood worker Peter Bugler – http://www.acorn-woodworks.com/.

- Center roof and columns were built on the ground and all raised in one day with a crane. Perfect fit. All poplar wood.

- Lower roof line was built in place using a traditional jig to lever rafters in place.

- Roof decking was saw milled on site and is 2-3” thick to accommodate the soil and plants of the living roof to come.

Living Roof

Recycled rigid insulation was laid on top of the roof decking, covered with a heavy duty EPMD liner (pond liner) and filter fabric. Approximately 5” of top soil/compost mix was bucketed up during workshops and planted with drought tolerant sedums.

- Living roofs help insulate against heat gain in summer and heat loss in winter as well as reduce runoff.

Strawbale Infill

We used 500+ bales as infill between the round wood columns, mostly during workshops.

Earthen Plaster – Scratch Coat

First of three layers of earthen plaster (clay & sand) goes on the interior of the strawbales. Wyatt Wizard Judd in action!

Lime Plaster – Scratch Coat

First of three coats of lime plaster (putty & sand) goes on the exterior of strawbales. Jason Judd plastering it up!

Masonry Stove

Finnish design stove that stores heat in it mass that slowly and evenly radiates. Only requires an arm full of wood a day! Ace stone work by Randy Bollinger.717.253.7978.

Final Earthen Plaster

Our favorite part has been the plastering. For the final plaster recipe we created a unique blend of kaolin clay, white sand, toilet paper, fine straw, and wheat paste to give a light colored finish.

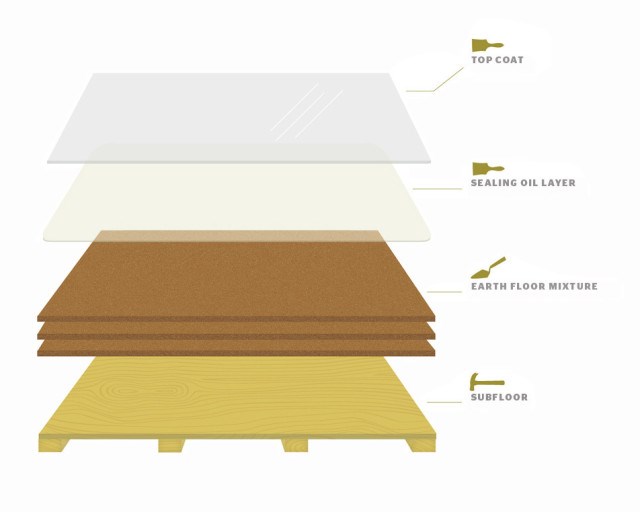

Finish Earthen Floor

The final earthen floor has turned out beautiful and strong. Mixing sifted clay, sand and straw the final layer is hard troweled on. When dried it is heavily oiled with linseed. Once the oil dries we give a light sand and apply a wax. The finish feel is super smooth and durable.

We moved in the Fall of 2016 and are very much enjoying a home that nurtures the mind, body, and soul.

Come see the house during one of our workshops or at the Paw Paw Fest!

More on Earthen Plasters

Clay and lime plasters bring a natural beauty and harmony to your living space. They are easily applied to existing walls including painted drywall to create texture and natural depth.

Natural plasters help balance moisture, regulate temperature, and sound. They transform the feeling of a space, adding a soothing energy that naturally relaxes. Also good in high moisture areas like kitchens, bathrooms, and laundry rooms.

Gary Laity

Clay and lime plaster on drywall works by first applying an appropriate primer with sand on existing surface (painted or not). The sand adds ‘tooth’ for the coat of clay or lime plaster mix to ‘key’ into. Finely blended clays, sands, and pigments are mixed and applied in a thin 1/8” layer using flexible Japanese trowels. The result are walls and ceilings that breath life and depth into your living space.

Clay and lime plasters can also be applied in lieu of drywall in new construction by adding wooden lath over 2”x4” framing. Plastering on lath offers a thicker and richer application of plaster that adds texture and softening to straight walls.

Clay and lime plasters can also be applied in lieu of drywall in new construction by adding wooden lath over 2”x4” framing. Plastering on lath offers a thicker and richer application of plaster that adds texture and softening to straight walls.

New construction also offers the potential to use a natural fiber as your wall infill. Our favorite choice are light-clay-straw-slip that doubles as insulation and a perfect plaster surface. Light-clay-straw-slip is straw dunked into a mud slurry to bind it together and packed between wall studs using a moveable form. It offers one of the most economical and ecological wall options in conventional structures. Works well in homes, and outdoor structures such as workshops, play houses or animal housing.

Cedar Ridge

*Woodchips and wood shavings can also be used in place of straw. Loosely packed straw or chips maintains air pockets that act as thermal breaks.

Lime Plaster

For exterior and interior walls Ecologia uses traditional lime plasters for increased water resistance and durability. Lime plaster turns surfaces into art. Used since ancient times and still highly celebrated in Europe lime plaster adds a classic quality and look. Like earthen plaster lime can be pigmented with a vast array of natural colors and textured in various ways. Lime applies easily over brick, block, drywall, and lath. Lime plaster can be used on interior walls in place of earthen plaster.

Lime coated exterior at Long Creek Homestead

Lime plasters durability and beauty are attested to in the world’s most beautiful structures from the monuments of ancient Egypt to the Sistine Chapel. Also known as Venetian Plaster and traditional stucco lime plasters can be colorfully pigmented and Fresco painted. See Omega Products for colors.

‘Fresco’ paint in lime plaster is accomplished by added a pigmented wash to the plaster while still wet, leaving an embedded impression.

‘Fresco’ paint in lime plaster is accomplished by added a pigmented wash to the plaster while still wet, leaving an embedded impression.

*Hempcrete is made of hemp fiber & lime putty – used as wall infill.

Earthen Floors

The concept and look of earthen floors has come a far way from the ol’ dirt floor shack. Touché, they can bring a natural elegance and natural smoothness that feels and looks wonderful.

Earthen floors are basically clay plaster on the floor, the main difference being that the earthen ‘plaster’ on the floor gets heavily oiled and waxed when dry. The oiling of the earthen mix has a hardening effect that creates a durable and washable floor. The earthen floors in our home are testament to their durability with two dogs and a wild toddler!

Pigment can be added to the oil and wax to add unique coloring and stunning effect. Here our main room floor is pigmented with a natural yellow oxide.

Like clay plasters earthen floors are an easy retro-fit to existing or new construction. As long as the subfloor is secure, meaning little to no movement, an earthen floor can be applied as thinly as 2 inches…

Sukita Crimmel

Recommended resources:

- Using Natural Finishes: Lyme and Earth Based Plasters, Renders & Paints, by Adam Weisman and Katy Bryce.

- Earthen Floors: A Modern Approach to an Ancient Practice, by Sukita Crimmel and James Thompson

- Good article on earthen floors – https://www.pdxmonthly.com/articles/2010/5/27/spaces-earth-floor

*Michael Judd’s journey with natural building began while living with Mayan communities and fashioning structures from surrounding raw materials. His skills where honed through various apprentices and jobs in New Mexcio including; earthbag building, rammed earth, strawbale, light-clay-straw, adobe, cob, earthen and lime plastering, and earthen floors. His more recent work and combined skills are captured in the beauty and elegance of Long Creek Homesteads circular strawbale home and in custom work throughout the Mid-Atlantic region.

Posted In: Edible and Ecological Landscape Design